- Jaggakhedhi industrial area Mandsaur(M.P.)-458001

-

+91-9826966502

millmakermachinery@gmail.com

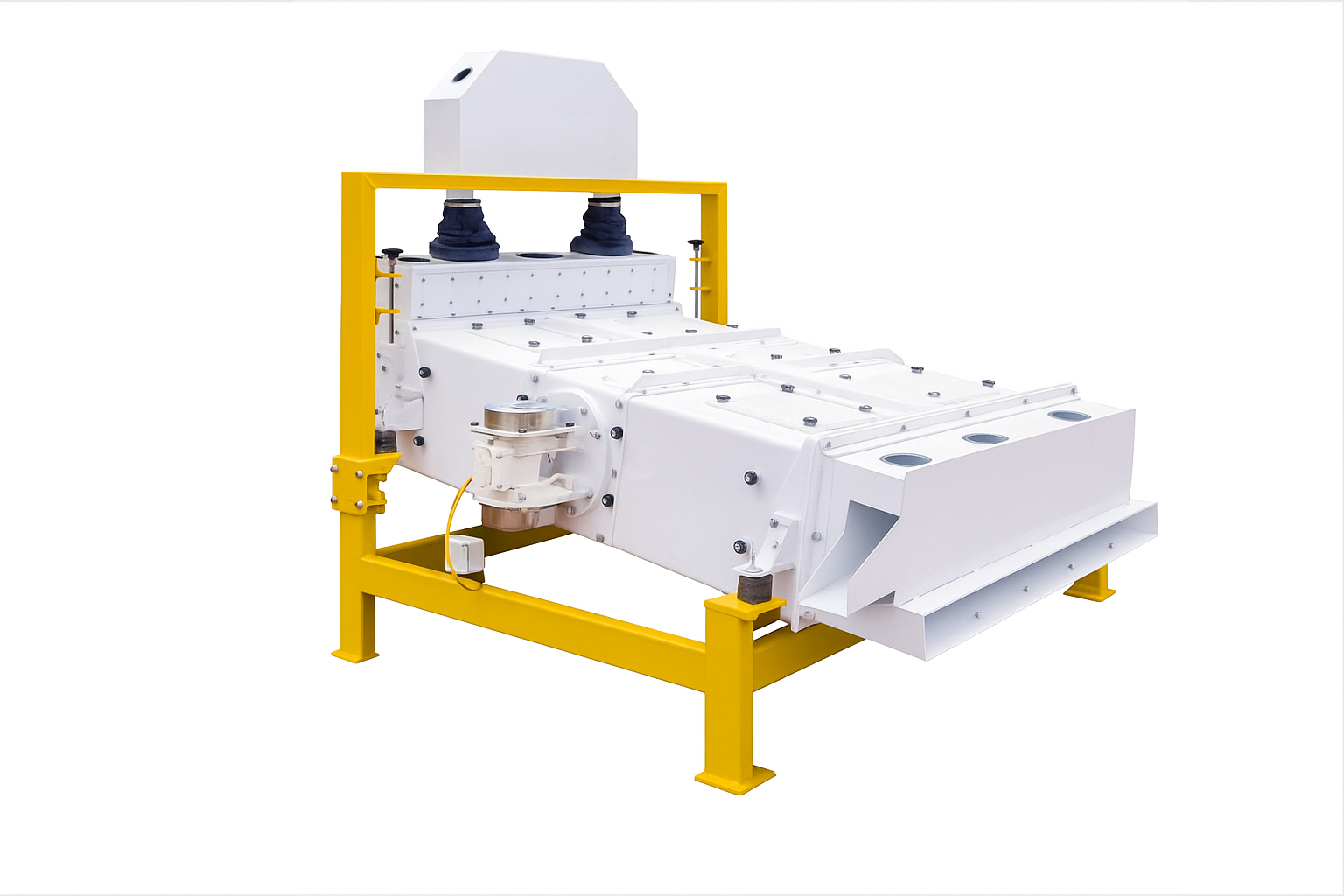

We are manufacturing a wide range of Vibro Screen Separator. These vibro screen separators are fabricated using high grade raw material & can achieve high performance efficiency, easy to use & durable. Available in standard specification, our vibro separator is available in 2 deck screen and 3 deck screen.

| Model | Power | Capacity in Wheat |

|---|---|---|

| MVS2-100/200 | (0.37 x 2) kw | 4 t/h |

| MVS3-100/200 | (0.37 x 2) kw | 4 t/h |

| MVS2-150/200 | (0.37 x 2) kw | 6 t/h |

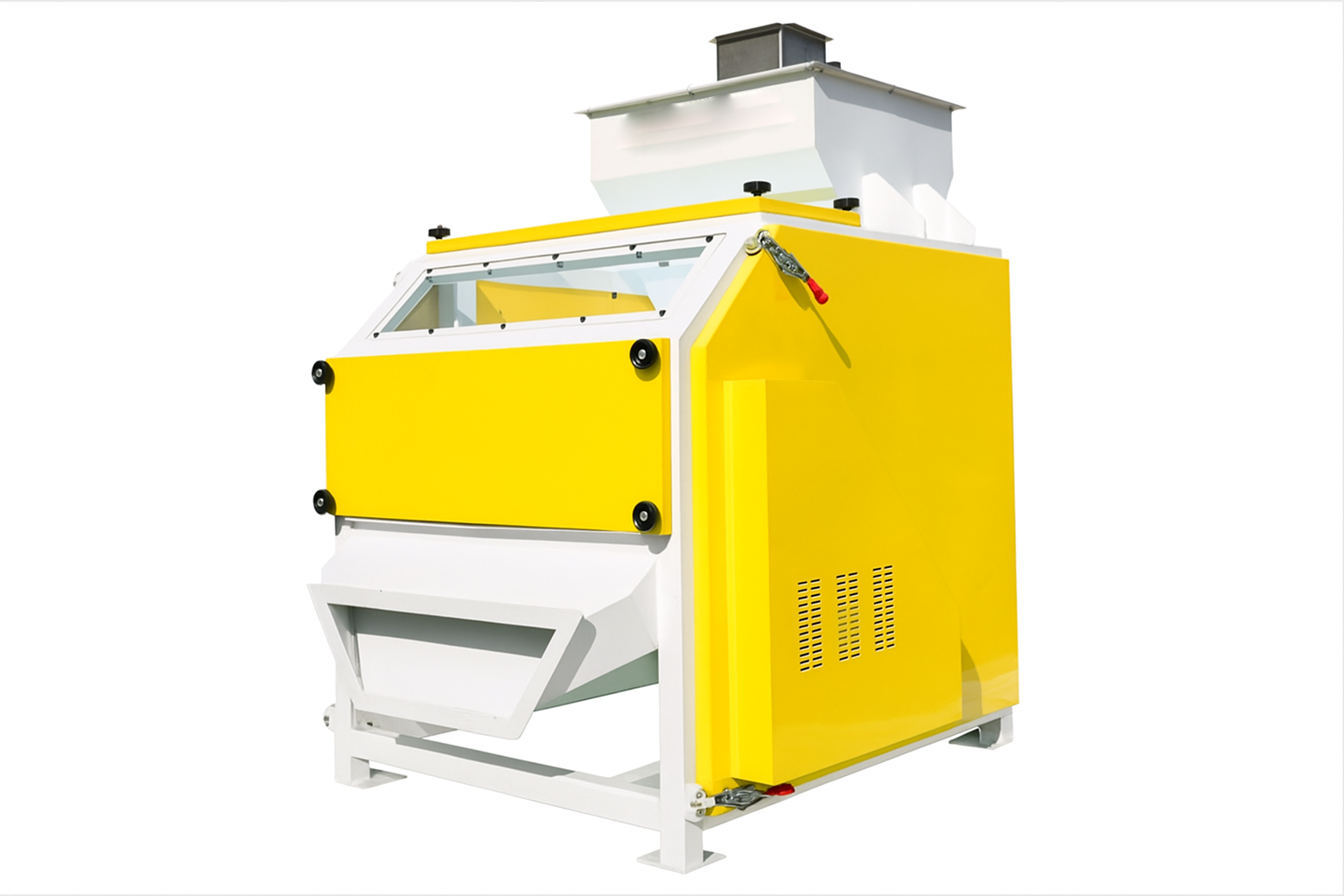

Vibro Destoner machine works based on the difference in grain specific gravity, grain size, shape and surface state. The working table is covered with a woven wire mesh bed, through which air flows from below. Heavy impurities such as stone are not lifted by air cushion and stay on the mesh bed. The vibratory motion of the table causes the heavy impurity (stone or sand) to be transported to the beginning of the regulating plate at far end of the machine.

| Model | Power | Aspiration | Capacity |

|---|---|---|---|

| MVD-65/120 | (0.37) kw | 70 m³/min | 3-5 t/h |

| MVD-100/120 | (0.37 x 2) kw | 100 m³/min | 4-6 t/h |

| MVD-120/120 | (0.37 x 2) kw | 130 m³/min | 6-8 t/h |

Magnet Destoner (Mud Ball Separator) – our magnetic destoner uses special strong magnetic roller at the front end of the conveyor belt, which can easily remove the impurities and minerals with weak magnetic component such as soil mud ball, light stone, brick tips, etc. in the material.

It is widely used in the field of grain, beans, spice and other food raw material selection. In the sorting process of many grain and foods, there will be some impurity such as soil block, light stone, brick tips, etc., which are difficult to be removed by sorting equipment such as metal detector, specific gravity separator, screening machines and destoner. Magnetic destoner is an expert to solve such problems.

| Model | Power | Capacity |

|---|---|---|

| MMD-75 | (0.37 x 2) kw | 3-5 t/h |

| MMD-100 | (0.37 x 2) kw | 4-6 t/h |

| MMD-150 | (0.37 x 2) kw | 6-8 t/h |

Gravity Separator are used for separating product of the same size but with different specific weight. They are used effectively for removing partially eaten, immature & broken seeds to ensure maximum quality of the fine product. Our gravity separator deck rpm control by automatic v.f.d system.

| Model | Power | Capacity |

|---|---|---|

| MGS-3F | (0.75 + 3.75) kw | 1-2 t/h |

| MGS-5F | (0.75 + 5.5) kw | 3-4 t/h |

| MGS-7F | (1.1 + 7.5) kw | 5-7 t/h |

Drum Sieve is suitable for multiple grains and spices such as wheat, pulses, rice, maize, coriander, ajwain, methi, etc. It efficiently separates coarse impurities such as pieces of straw, pouch, bag tapes, papers pieces of wood and leaves efciently. Drum Sieve machine protects damage for other machines of the plant.

| Model | Power | Capacity |

|---|---|---|

| MDS-750 | 0.75 kw | 15-25 t/h |

| MDS-950 | 0.75 kw | 25-50 t/h |

| MDS-1250 | 0.75 kw | 50-100 t/h |

Millmaker Machinery manufacturing best qualitty pulses hulling machine. This machine use for remove pulses and seed coat. Millmaker Machinery has stringent desing parameters of dynamical balancing, efficient drive & bearing and adjustable counter weight outlet controller, this leads to reduced power requirment for the process. Our hulling machine advanced features for whole machine degree adjustment and gap adjustment between stone and screens so that pulses and seeds have minimum brakage. Profitability is greatly improved due to lower power requirment combined with high throughput.

| Model | Power | Capacity |

|---|---|---|

| MHL-300 | 7.5 kw | 1.5 – 2.5 t/h |

| MHL-350 | 11 kw | 2.5 – 3.5 t/h |

| MHL-400 | 11 kw | 3 – 4 t/h |

| MHL-450 | 15 kw | 4 – 5 t/h |

Millmaker Machinery manufacturing best quality Splitter Fatka Machine. This machine is used for splitting pulses and removing seed coat efficiently. Designed with advanced features like dynamical balancing, efficient drive & bearings, and adjustable counterweight outlet controller, it ensures reduced power requirement and higher productivity. The machine also has degree and gap adjustment mechanisms between stone and screens, resulting in minimum breakage of pulses. Overall, it improves profitability with lower power consumption and higher throughput.

| Model | Power | Capacity |

|---|---|---|

| MSPL-600 | 2.25 kw | 3-4 t/h |

| MSPL-800 | 3.75 kw | 4-6 t/h |

We provide a wide assortment of material handling Bucket Elevators widely used in several industries and sectors. Our bucket elevator design and fabrication is very high quality. We use food grade rubber belt, special wing pulley, shovel type bucket in our elevator so due to its use, the loss of your product breakage will be minimized.

| Model | Power | Capacity |

|---|---|---|

| MLTBE-100 | 0.74 kw | 3-5 t/h |

| MLTBE-125 | 0.74 kw | 5-8 t/h |

| MLTBE-150 | 1.1 kw | 8-10 t/h |

| MLTBE-175 | 1.5 kw | 16-20 t/h |

| MLTBE-200 | 1.5 kw | 20-25 t/h |

| MLTBE-250 | 2.25 kw | 25-35 t/h |

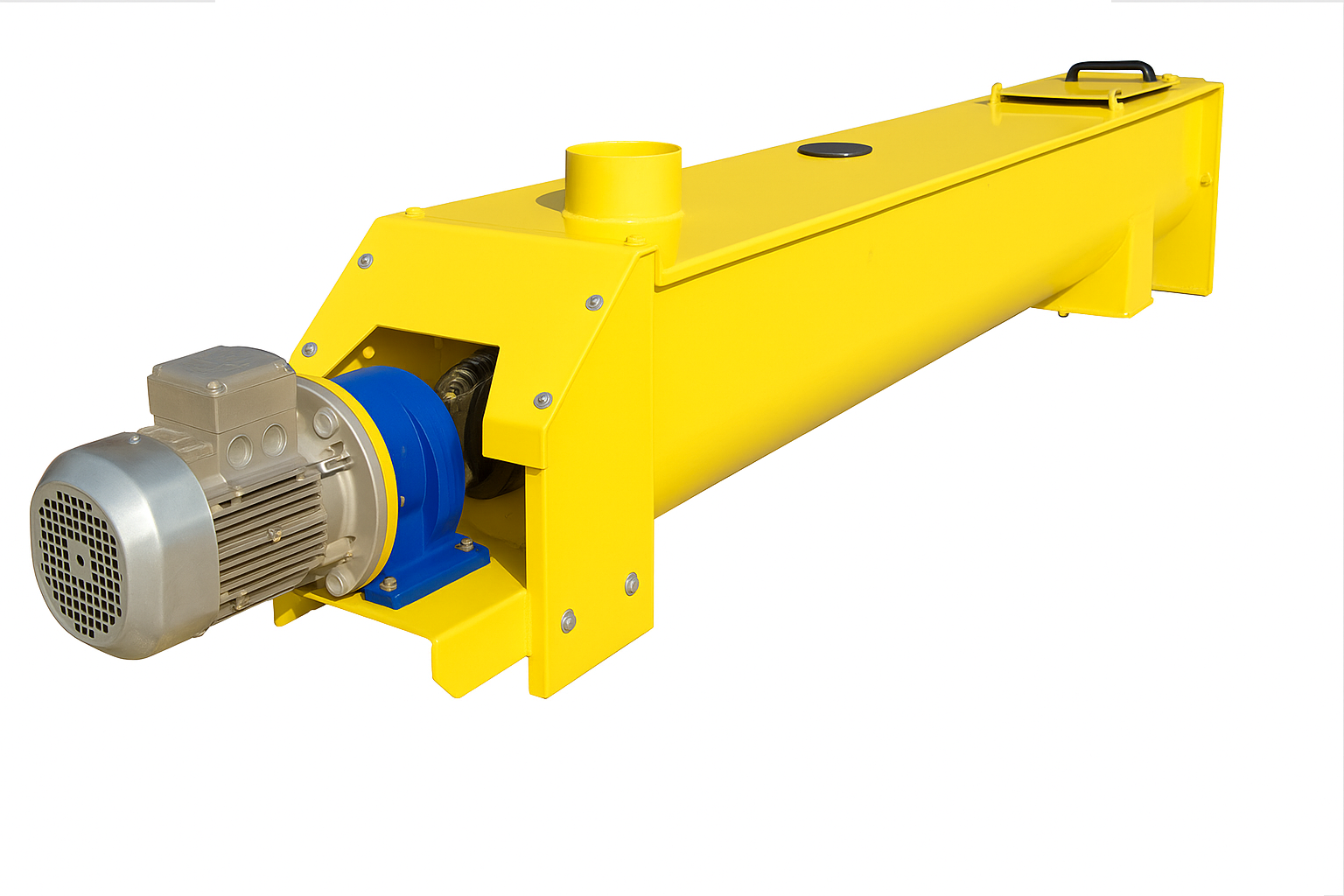

The Screw Conveyor or Auger Conveyor is designed in many variations and subsequently, applicable to many mixing installation and techniques. The rotating helical blade transports powder, seeds or granular material horizontally or upwards in the vessel for optimal mixing. Depending on your requirements such as capacity, transport height and bulk density, we customize screw conveyor to offer you the best possible solution.

| Model | Power | Capacity |

|---|---|---|

| MSC-150 | 0.75 kw | 2-4 t/h |

| MSC-175 | 0.75 kw | 4-6 t/h |

| MSC-200 | 0.75 kw | 6-8 t/h |

| MSC-250 | 1.5 kw | 8-10 t/h |

| MSC-300 | 1.5 kw | 10-12 t/h |

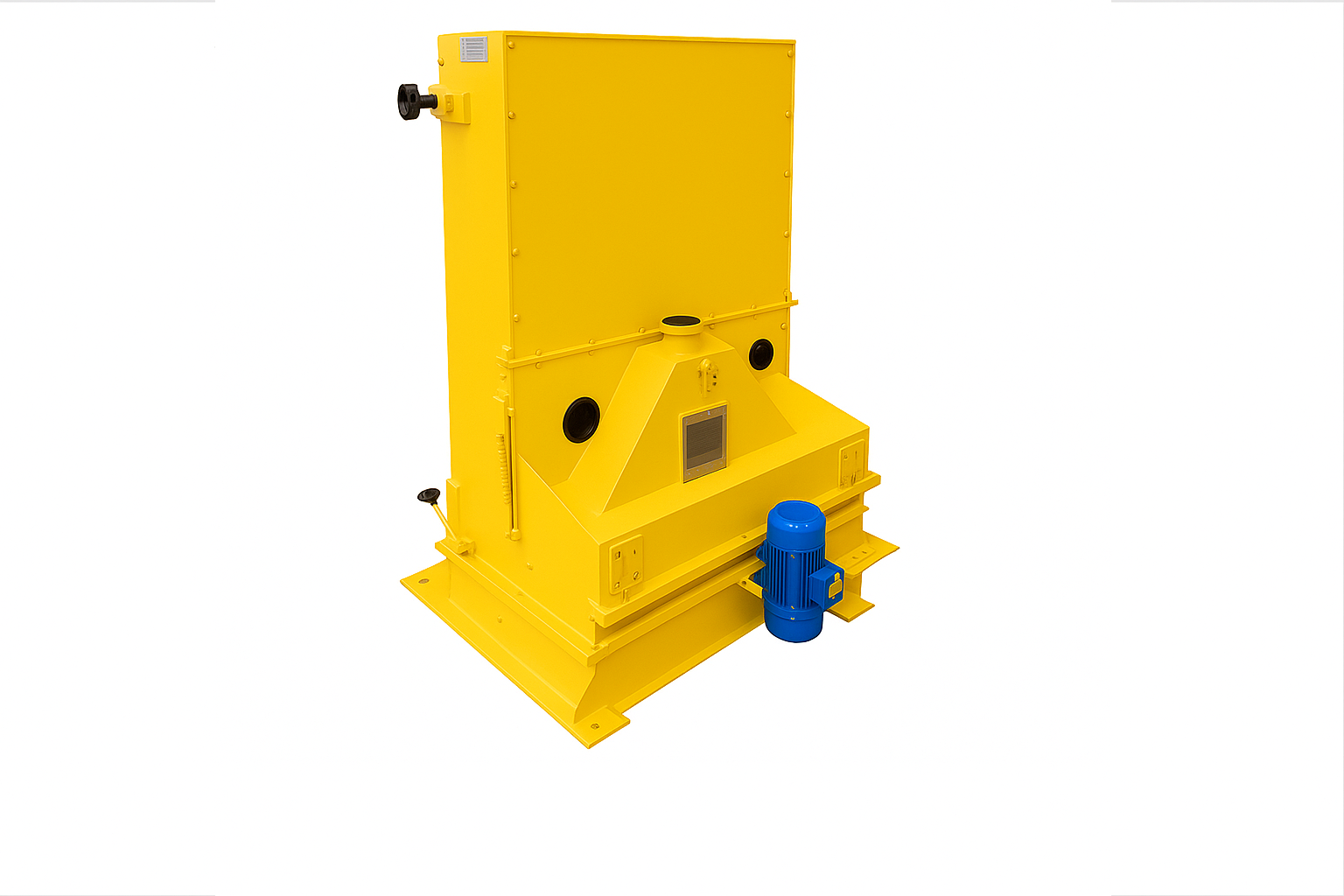

The Vibro Aspiration Channel is mainly used for the separetion of husk and lighter weight particles from wheat, pulses, barley, oats, corn etc. At cleaning section of the mill, the grain is fed through the feed - shoe that is kept horizontally oscillating by a vibro motor at the sametime the cleaned product keeps the outlet, the lighter particles are removed and carried in to the aspiration channel and discharged to the waste conveying line by air flow.

| Model | Power | Capacity |

|---|---|---|

| MVS-1000 | 0.37 kw | 3-4 t/h |

| MVS-1500 | 0.37 kw | 4-6 t/h |

We have leading specialization in manufacturing of truck loader - unloader mobile conveyor unit for all applications like boxes, cartons, bags, etc in warehouse, botteling, distileries, pharmaceuticals, etc or any other places where material needs to be moved rapidly & effciently. This conveyor is reduces maximum labour & saves time. Feauters are easy movability, slider bed design, zero maintenance.

| Model | Power | Capacity |

|---|---|---|

| MTL-10 | 1.5+0.75 kw | 100 kg / bag |

| MTL-15 | 2.25+0.75 kw | 100 kg / bag |